Kana iyondiro yendarirainoshandiswa kwenguva yakareba, pamusoro peplate yendarira ichava yakashata, uye inogona kuita kuti ndiro yendarira iite oxidize, iyo inokanganisa kushandiswa kunoramba kuchishandiswa kweplate yendarira.Kupukuta ndiro yendarira kunogona kuvandudza kutsetseka kwepamusoro kweplate, uye zvakare Iine imwe anti-oxidation basa, saka ndeipi nzira yekupukuta yeplate yendarira?Ndeapi matanho anofanirwa kutorwa paunenge uchipukuta?

1. Brass plate polishing process

1. Munguva yekushanda kwekutsvaira, gadzira sarudzo yakakodzera yemhangura yekushanda maererano nemirairo, uye edza kuishandisa munzvimbo inofefetera pamhepo yekupisa, kuitira kuti irege kukanganisa kushandiswa kwekugadzirisa kwekugadzirisa.

2. Mushure mekugadzira mushonga wekupolisha mhangura, sora ndiro yendarira mumushonga wekupukuta, bvisa ndiro yendarira mushure memaminitsi 2-3, uye pakarepo uiise mumvura yakachena yekuchenesa, uye kuchenesa mvura yakasara.

mushonga pane workpiece kudzivirira kukanganisa kunotevera kushandiswa.

3. Mushure mokunge ndiro yendarira yakasvibiswa uye yakacheneswa, inogona kupinda mune inotevera nzira yekupfapfaidza uye passivate ndiro yendarira.Kuti udzivise ndiro yendarira kubva pakuchinja ruvara mushure mekupenya, zvakakosha kuomesa-mhepo uye passivate ndiro yendarira munguva.

4. Munguva yekutsvaira, kana zvikaonekwa kuti kubwinya kwepamusoro kweplate yendarira hakusviki zvinodiwa zvinoenderana, zvigadziridzo zvakakodzera zvinogona kuwedzerwa kune mhinduro yekutsvaira.Muyero wekuwedzera ndeye 1% -2% yeiyo yekutanga polishing mhinduro.Iyo yekuwedzera ndeyekutevera shoma shoma Multiple nheyo.Kana iyo ichiri kusasangana nezvinodiwa mushure mekuwedzera kuwedzera, inoda kutsiviwa nemushandi mutsva wekupolisha.

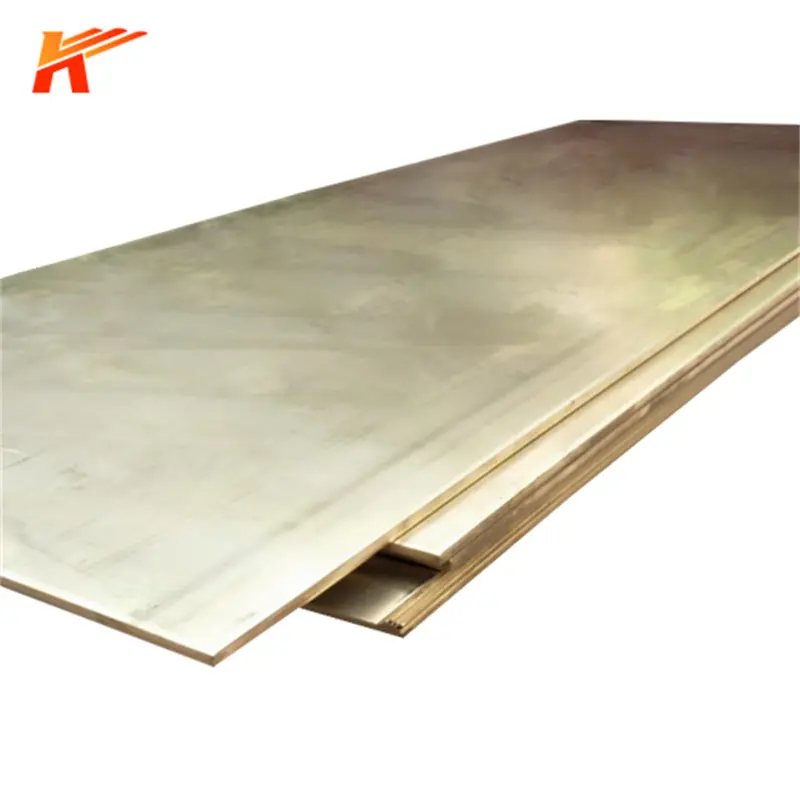

ndiro yendarira

2. Kuchengetedza kwendarira yeplate polishing

1. Edza kushandisa epurasitiki pp matangi kune tangi yekushanda ine mvura inopenya, uye usashandise simbi, ceramic uye mamwe matangi anoshanda.

2. Panguva yekutsvaira, teerera kuzunungusa kana kushandura workpiece kuti udzivise kupindirana kwepamusoro pebasa rekushanda kubva pakusangana kwakanaka nekushanda kwemvura.

3. Paunenge uchipukuta, workpiece haigoni kukwenenzverwa zvakanyanya panguva imwe chete, uye imwe gap inofanira kusiiwa pakati pezvishandiso kuti zvidzivise kuipa kwekugadzirisa.

4. Mushure mekunge kupenya kwapera, mushonga wemvura wakasara unofanirwa kucheneswa kuti urege kukanganisa kushandiswa kwayo panguva inotevera.

5. Mushure mekupukuta, isa ndiro yendarira munzvimbo inotonhorera uye ine mhepo yekuchengetera.

6. Mushonga unopenya unoparadza kusvika kumwero wakati.Panguva yekushanda, kutarisirwa kunofanira kutorwa kuchengetedza mvura kubva pakusangana neganda remunhu.Bata zvine hungwaru kudzivirira mvura kubva pakupfapfaidza.

7. Mushure mekugadzirwa kwemakemikari, zvakakosha kuita kurapa kwekudzivirira munguva.Soak mumhangura inodzivirira mumiririri we30 seconds, iyo inogona kuvandudza oxidation kuramba kweplate yendarira.

Nguva yekutumira: Mar-03-2023